Are you looking for the right aluminum die casting manufacturers? You may have scrolled a lot but can not decide which is the best. If I am right, then you are definitely in the right place. We have brought you this guide to help you in this case. It mainly highlights the top 10 aluminum die-casting suppliers worldwide in 2024.

Top 10 Aluminum Die Casting Manufacturers in The World 2024

Deciding between aluminum die-casting manufacturers is always challenging. Some foundries might not do die-casting, while others may only focus on die-casting. In addition, it usually takes time to research through Google.

In each section below, we will mainly highlight four primary aspects of a factory. First, we will discuss the company and its main services. Does the company only focus on aluminum die-casting? What other casting methods does it usually provide? You can also check whether the factory offers surface finishes for aluminum parts. Later, we will learn their pros and cons. All these factors can help you find the best aluminum die-casting manufacturers for your project.

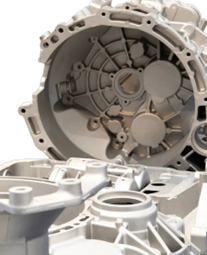

Castiny Factory #1 CNM TECH Co. Ltd.

This die casting factory is the best on the list. It offers all the necessary services to prepare an aluminum metal part, from design to finishing.

This factory is in Guangdong, China. Since 2005, it has been one of the top 10 aluminum die-casting manufacturers in China. Note that this company always tries to follow the latest technology. To keep the standards, they keep the latest machinery. As a result, it ensures the highest quality of the metal parts. The best thing is that you can achieve up to ±0.01mm tolerance in each metal part.

Main Services

- Aluminum die casting: prototyping, tooling, aluminum die-casting, machining, and surface finish.

- Zinc, Bronze, and Magnesium die-casting:

- You can create HPDC and LPDC aluminum die-casting metal parts.

- Aluminum gravity casting

- Aluminum sand casting

- Precision CNC Machining

- die casting mold

Pros

- This aluminum die-casting factory provides a full range of services from casting to finishing. It also offers rapid prototyping with a step-by-step development process.

- Diverse die-casting capabilities

- Multiple casting methods

- High tolerance machining services: you can achieve tolerance up to ± 0.01 mm.

- Excellent customer service

- Excellent customer feedback

- The cost is relatively cheaper than other brands mentioned on this list.

Cons

- They usually don’t offer other casting services, like investment casting or shell mold casting.

- From this factory, you will mostly find aluminum die-casting products. Some are made of zinc, magnesium, and Bronze.

- CNM TECH Co., Ltd may not be suitable for steel or other metals. However, you can get various steel forging services from this factory.

Foundry #2 Ryobi Limited

Japanese Ryobi Limited can be your next best pick. This aluminum die-casting supplier started its business in 1943. You may find them as one of the leading aluminum die-casting manufacturers worldwide in 2024.

The company is in Hiroshima-ken, Japan. Regarding aluminum die-casting products, it mainly focuses on vehicle parts. Honda, Volkswagen, and Ford are some of its everyday customers.

Main Services

- All metals die casting services for vehicles only

- Builders Hardware

- Printing Equipment

Pros

- This factory mainly supplies products to automotive industries.

- They can make various metal parts, including aluminum die casting.

- Advanced machinery and technology for precision casting

- Excellent customer feedback.

Cons

- Other casting methods, such as sand casting, gravity casting, and investment casting, are not included in their service list.

- You can only get vehicle parts, so customers from different industries may not benefit from this factory.

- The product service list on the website is unclear, making it difficult to understand their primary services.

- Contacting customer support is relatively tricky.

Foundry #3 SintoKogio

Our next best pick is another Japanese aluminum die casting manufacturer. While the company was founded in 1934, Sintokogio was reborn in 1960. Their headquarters is in Aichi, Japan.

Regarding aluminum casting, Sintokogio mainly focuses on cold box molding and shell molds. Their products are widely used in aircraft and car engine parts. However, you may have limited options here. But for car parts, this factory can be your good choice.

Main services

- Foundry: Aluminum casting, green sand molding, v-process, and chemically bonded metals

- Surface Treatments

- Powder treatment, force sensors, electric cylinders, material handling, and flooring

Pros

- Multiple casting capabilities.

- After casting, this factory also offers extensive surface treatment options.

- Their latest technology ensures high-precision metal parts.

- Excellent customer support services.

Cons

- For aluminum casting, you can only get aluminum gravity casting and low-pressure aluminum casting. Therefore, you can get limited options for aluminum die-casting parts.

- The cost is relatively higher.

- Their surface treatment involves removing, peeling, roughening, polishing, strengthening, micromachining, and seeing. However, anodizing, e-coating, and other finishing methods are crucial for aluminum die-casting parts.

Foundry #4 Redstone’s President Eric Milling

This plant is one of the new aluminum die-casting manufacturers. It opened in 2018 and has its headquarters in Ohio, USA. It has four main branches: Brazil, China, India, and Mexico.

Aluminum die casting is one of this company’s main products. Although the website doesn’t mention it, they mentioned that they can take mass production orders. You can get all types of services, from design to manufacturing and testing.

Main Services

- Die casting services include zinc die casting, aluminum die casting, and copper die casting.

- Investment casting

- Sand casting

- Metal Fabrication: sheet metal fab, CNC machining, and metal injection molding services

- Plastic injection molding services

Pros

- This aluminum die-casting manufacturer offers zinc, aluminum, and copper die-casting. They specialize in aluminum die-casting services.

- High-quality metal parts with tight tolerances

- Additional casting methods are also present. You can work with other metals like steel, copper, and titanium.

Cons

- Although they offer CNC machining for surface treatment, it is not enough. As you know, aluminum metal parts need other types of finishing methods. Typical examples are anodizing, e-coating, polishing, painting, and more.

- The website doesn’t talk about different aluminum casting services.

- Their aluminum die-casting parts are relatively expensive. In this case, GC precision mold aluminum casting parts are much better.

- Unable to create custom messages through the website

Foundry #5 Kormax

This alujminum die casting company, which is part of Milson Group, was founded in 1947 and has its headquarters in Palmerston North, New Zealand.

The best thing about this manufacturer is that they deal with various alloys. It includes aluminum, iron, nickel, stainless steel, and steel. However, aluminum alloys include A713, A35, A355, A356, A357, A319 and A380.

This aluminum alloy die-casting manufacturer mainly offers HPDC, LPDC, and gravity die-casting services. They usually make aluminum parts from 0.1g to 15kg.

Main Services

- Aluminum die casting

- Sand casting

- Investment casting

- Centrifugal casting

- Continuous casting

- Extruded

- Custom Manufacturing

- Machining

Pros

- High-quality aluminum die casting services with high precision

- Expertise in handling complex designs and large volumes

- This factory offers other casting services as well. You can work with different metals, such as steel, brass, and copper.

- You can order for custom manufacturing.

Cons

- The company only offers various machining services, but other finishing methods may not be available.

- Higher price compared to other brands on this list. Custom manufacturing and additional machining can be costlier than standard services.

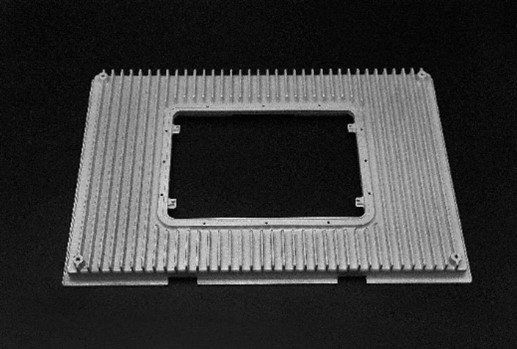

Foundry #6 Sunrise Metal Foundry

Sunrise Metal is a Chinese aluminum die-casting manufacturer. It was established in 2011, but it started making aluminum die-casting products in 2013. Its headquarters are in Kunshan, Jiangsu, China.

Sunrise Metal offers all types of casting services. All you need to do is tell them what you want to make. They will design, cast, machine, and give it a good look. Based on the information you provided, they will create the metal part. However, it mainly supplies metal parts to the medical, marine, automotive, and telecom industries.

Main Services

- Aluminum die casting services: prototyping, tooling, aluminum die-casting, machining, and surface finish.

- Rapid prototyping

- Die casting tooling

- Secondary CNC machining

- Surface Finishing

Pros

- This aluminum casting factory offers cheaper metal parts with faster production.

- You can get all aluminum metal casting services, from casting to finishing.

- Excellent Customer service

- Rapid prototyping services

Cons

- While this aluminum die-casting factory offers a wide range of services, its primary strength lies in aluminum only. However, if you need specialized services, this manufacturer may be unsuitable.

- Although the customer service portal is convenient, you can get a slower response, generally in 1 day.

Foundry #7 VJP Aluminum Sand Casting Foundry

Our next best pick is VJP from India. This company was established in 1983. Their headquarters is in Tamil Nadu, India.

Regarding die-casting services, this company only focuses on aluminum gravity casting. Specifically, they deal with two main types: stationery and tilt die-casting. Thus, you may get limited options for your aluminum metal parts. However, they offer a wide range of aluminum finishing services.

Main Services

- Gravity die-casting

- Aluminum sand casting

- Surface Treatment methods

- CNC machining

Pros

- This foundry specializes in gravity die-casting services. You can technically order all types of metal parts from this factory.

- High precision with tight tolerances

- You can also get a wide range of surface finishing methods. They offer anodizing, blasting, powder coating, liquid painting, Alodine, and chromatin.

Cons

- Customer support is not fast and convenient.

- Only specializes in gravity die casting. For other aluminum metal parts, this factory may not be suitable.

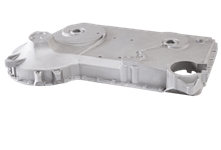

Foundry #8 PHB Incorporation

This aluminum die casting factory has been in the die-casting business since 1906. It became incorporated as PHB in 1984. Its headquarters are in Pennsylvania, USA.

This company also provides three-stage manufacturing. You have already seen similar applications in GC Precision, Sunrise Metal, and Kormax. First, prototyping lets you make unique metal parts. Second, depending on the prototype, you can use it for small amounts or mass production. Third, cleaning the surface gives those metal parts a unique look.

Main Services

- Aluminum die casting

- CNC machining

- Casting sourcing

- Tool and Die

- Zinc Die Casting, plastic molding, injection molding

- 3D printing

Pros

- Excellent quality from design to production

- You can also get custom manufacturing services from PHB.

- This aluminum die-casting manufacturer also specializes in various types of aluminum finishes. Popular methods they offer are powder coating, anodizing, e-coat, chrome, and chromate.

Cons

- Except for die-casting, this foundry doesn’t offer other casting services.

- PHB aluminum parts are relatively expensive compared to the quality and shipping.

- Customer support is also not convenient. You may have to wait for a long time for a single response.

Foundry #9 Sirvanli Aluminum Casting

Sirvanli started its business in 1980. Its first product was die-casting metal parts. Later, it added machining and finishing methods.

The company is in Kocaeli, Turkey. This aluminum die-casting factory offers a wide range of die-casting services. Among them, gravity and HPDC are the most common.

Main Services

- Gravity die-casting

- Sand casting

- Higher pressure die-casting

- Machining

- Other Finishing Methods

Pros

- Offers diverse aluminum casting capabilities. You can get all types of aluminum metal parts from this foundry.

- Provides precision machining, which ensures high-quality final metal parts

- Relatively cheaper than other brands

- Various aluminum finishing methods

Cons

- The website is difficult to navigate. You may have to struggle to find the English translation. You can find it in the upper right corner of the navigation bar.

- Poor customer support & you may have to wait a long time for their responses.

Foundry #10 American Precision Die Casting

Our final pick is American Precision Die Casting. As the name suggests, this is an American Company. It started its journey in 2005 and is headquartered in Cuba, USA.

APDC only deals with aluminum die casting. They make metal parts for the military, automotive, aircraft, and electric industries.

Main Services

- Aluminum die-casting: designing, tooling, manufacturing, and finishing processes

- Machining

- Finishing Services

Pros

- The company offers all types of machine services.

- Excellent customer support services.

Cons

- This aluminum die-casting manufacturer only specializes in A380 aluminum alloy. If you are looking for other alloys, this factory may not be suitable.

- Again, this factory is not the place to go if you are looking for other casting methods, like gravity casting or investment casting.

- The aluminum parts from this factory are generally more expensive than other brands.

How did we Choose the Best Aluminum Die Casting Manufacturer?

You have already gotten acquainted with the world’s top 10 aluminum die-casting manufacturers. Each brand is famous for its unique services and qualities. As you know, hundreds of manufacturers are making aluminum casting parts. So, is it normal to raise questions like how we made this list? What did we consider when selecting them? Let’s check them out.

Factor #1 Production Capacity

First, we ensured the aluminum casting factory could meet your volume needs. Whether you need a small batch or mass production, these manufacturers can meet your demands.

We considered their maximum output. Can they handle large orders? Scalability was also important. Can they increase production if needed? We also checked their ability to handle peak demand periods. Quality should stay the same during busy times.

Factor #2 Technical Capabilities

The quality of the aluminum die-casting parts depends on technology. As you know, the latest machinery always gives you the highest precision. Therefore, we chose an aluminum die-casting manufacturer with the latest technologies.

We also focused on engineering expertise in addition to machinery. What kind of machining services do they offer? In this case, aluminum finishing is crucial.

Factor #3 Location & Logistics

We also considered their location. Shipping costs and lead times matter a lot here. As you know, a nearby location can reduce expenses and speed up delivery times.

This factor generally helps your business get the best price. Can they reduce transport costs? Can aluminum die-casting manufacturers offer international shipping? These factors usually ensure smooth operations.

Factor #4 Experience & Reputation

We also considered their experience and reputation. How many years have they been in the industry? Client testimonials were also crucial in the considerations. We also looked at case studies. Did they receive any industry awards? Certifications also matter here. These factors show reliability and expertise.

Factor #5 Quality Standards

We ensured that the products met quality requirements. Do they comply with industry standards? We verified their quality control processes. Certifications like ISO 9001 are crucial here.

Factor #6 Customer Service

Finally, we evaluated the customer reviews. How quickly do they reply? Are their customers satisfied with their responses? We also looked at their willingness to support and provide solutions.

Frequently Asked Questions

What is the best aluminum for die casting?

The best aluminum for die casting is A380 or Alloy ANSI/AA A380. There are several reasons behind this. First, it has excellent fluidity. Second, it offers excellent corrosion resistance. As a result, you can use this aluminum alloy in a wide range of applications. Third, it has excellent mechanical properties. The high strength-to-weight ratio makes it more popular in diverse industries. Finally, they are lightweight and easy to get metals.

How do I choose a casting method?

It mainly depends on your project needs. What type of materials does your project require? What is the complexity of the design? Whether you need a small batch or mass production? You can choose the correct casting method for aluminum parts based on all this information.

How many types of die-casting are there?

The type may vary based on different factors. For example, if you consider the kind of chamber, you can classify die-casting into two main types: hot and cold chambers. There are also two types of pressure die-casting: HPDC and LPDC. Other types, like gravity, vacuum, squeeze, and semi-solid die-castings, are also noteworthy.

Contact Us Today

Contact us today for any die-casting services. We offer high-quality aluminum die casting tailored to your needs. Our team is always ready to assist with your project from design to finish. Reach out now to discuss your needs and get a free quote.

CNM Die Casting is your one-stop, complete service Die Caster for various die casting parts including aluminum die casting, investment casting, sand casting. We offer you a single source for engineered die castings, together with cutting-edge engineering resources, advanced production capabilities and complete secondary finishing.

CNM Die Casting is your one-stop, complete service Die Caster for various die casting parts including aluminum die casting, investment casting, sand casting. We offer you a single source for engineered die castings, together with cutting-edge engineering resources, advanced production capabilities and complete secondary finishing.