Table of Contents

ToggleCNC Machining Services: Precision Redefined

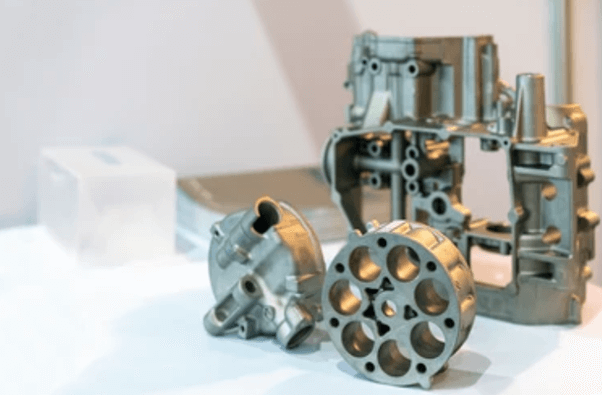

CNC machining, a technology that has redefined precision in manufacturing, offers greater accuracy, speed, and efficiency than ever before. Whether you’re crafting complex components for aerospace or intricate parts for consumer electronics, precision machining solutions have become the backbone of high-quality production processes. At TheDieCasting.com, we take pride in our ability to deliver world-class CNC machining services that meet the exacting standards of today’s industries. Let’s explore how our expertise as a trusted CNC machining parts manufacturer ensures exceptional results.

CNC Machining: A Foundation for Excellence

CNC, or Computer Numeric Control, machining applies computers that help drive tools accurately. Compared to normal techniques, technological innovation in CNC reduces the probability of human interference, resulting in accurate outcomes. With advances in high-speed machining, manufacturers can now achieve tight tolerances and superior surface finishes in record time.

Welding Cast Aluminum: A Comprehensive Guide

Can You Weld Cast Aluminum? A Complete Guide

Injection Mold Price

Unlock High-Performance, Cost-Effective Solutions for Your Injection Molds

Get a Quote

At TheDieCasting.com, we leverage these technologies to provide superior precision machining solutions for the automotive and electronics industries. Ensuring our clients utilize advanced tools and software we optimize our time and ultimately minimize our costs of production without compromising on the quality of our services.

How CNC Technology Works

In a nutshell, CNC machining entails using a computer operating tool to create tangible parts corresponding to the design. This process usually begins with CAD or Computer Aided Design software that will locate the piece’s specifications or part needed. Engineering drawings are used to develop instructions that workers follow while operating the CNC facility. Through this efficient process, it is possible for those at TheDieCasting.com to guarantee that every creation is made to a proper standard.

Why Choose CNC Machining?

The Accuracy Factor

The degree of accuracy that is associated with CNC machining is exemplary. Complex shapes with tight tolerances can be machined to perfection as the tool must meet those requirements; this should be considered when designing for applications such as in the medical industry or aerospace. At TheDieCasting.com, our CNC machining service manufacturer expertise ensures that every piece meets the highest quality standards, regardless of complexity. It results in the high credibility of the services we offer to support the business in other crucial projects.

Speed and Scalability

The demand for high-speed machining has surged as businesses strive to meet tight deadlines without compromising quality. No technology is better suited for making complex and accurate parts in large quantities than CNC machining. This is why TheDieCasting.com invests in cutting-edge technology to provide efficient CNC machining services in China, catering to global markets with swift turnarounds.

The skills and experience highlighted here mean that both the small startup business and the large enterprise will get the best solutions wherever they are located, whenever they need them, and in the quantities they require. Whether you require one piece prototype, or one thousand components, these procedures set can be sized appropriately.

Material Versatility

The application of CNC is versatile because it can cut, shave, or engrave different kinds of material, which include metals such as aluminum, steel or titanium, plastics, and composite materials. This versatility allows businesses to explore innovative designs and achieve robust products, all crafted under the expertise of a leading CNC machining parts manufacturer like us.

Further, we have a team at TheDieCasting.com who can assist customers regarding the materials best suited for the projects. This guarantees that every aspect has considerable endurance and has been designed to perform as planned.

Technology In Use – The CNC Machining Process

The current CNC industry remains dynamic owing to developments in software technology, tools, and machinery that form the basis of this technology. High-speed machining, for instance, utilizes state-of-the-art equipment to enhance productivity and reduce waste. This is particularly because, at TheDieCasting.com, we always adapt to new technologies in this sector to introduce these advancements to our clients.

Automation: Efficiency Redefined

Automation is a key aspect of modern CNC machining, significantly reducing the need for human intervention and improving the accuracy of the process. This allows us to offer scalable precision machining solutions that meet the diverse needs of our clientele, while also ensuring consistent quality and efficiency.

Multitasking capabilities of contemporary machines, including 5-axis machines, enhance efficiency by allowing complicated shapes to be formed in a single machining session. These capabilities make it possible for TheDieCasting.com to generate precise designs remarkably faster.

Why should you choose TheDieCasting.com as Your CNC machining source?

Manufacturing partnerships are vital, and choosing the right partner is always crucial. As a reliable CNC machining service manufacturer, TheDieCasting.com has built a reputation for delivering quality, precision, and value.

A Commitment to Quality

We acknowledge that the quality of your components determines your product performance. That is why we maintain strict quality control measures at each link within the framework of generating the final product. From raw material selection to final inspection, our CNC machining services adhere to the strictest standards.

At this stage, we state our fidelity to high quality doesn’t end. We also automate the measurements using advanced metrology tools to confirm that each part meets the required specifications regardless of the severe project it will be used.

Global Reach, Local Expertise

As a provider of CNC machining services in China, we combine local expertise with global capabilities. All our facilities are well equipped with appropriate machinery and, most importantly, personnel who perfectly complete each assignment.

This wealth of years of experience handling clients from all fields has given us a wealth of knowledge as to what businesses go through. This knowledge allows us to deliver tailored precision machining solutions that address specific needs.

Solutions with a sprinkle of individual and/or client demand varieties.

This means that every project is different in some way and will always have its particular set of needs fulfilled. Here, at TheDieCasting.com, we approach every client by listening and understanding the exact needs of the clients. Ranging from making sample designs to mass productions, we possess the capacity to handle all types of designs.

We also have design enhancement, where we assist clients in enhancing their designs for better performance or ease of manufacturing. This means that every project developed holds the most value in line with Feigenbaum’s collaborative approach.

Applications of CNC Machining

CNC machining is highly flexible, which explains why it will suit many industry applications. Here are some key areas where our expertise as a CNC machining parts manufacturer shines:

Aerospace

When it comes to manufacturing in the aerospace industry, tolerances are a thing of great importance. CNC machining is preferred for producing complex pieces that must be performed in extreme conditions. At TheDieCasting.com, our advanced high-speed machining capabilities ensure the production of parts that meet rigorous aerospace standards.

In this field, our experience is in applications such as the fabrication of turbine blades, structural parts, and other critical items that call for high dimensional accuracy and strength.

Automotive

The automotive industry relies heavily on CNC machining services for durable and precise parts, from engine components to custom accessories. As a leading CNC machining service manufacturer, we ensure that every part contributes to the safety and performance of vehicles.

The fact that we can provide components that are not only light in weight but strong, also

can contribute towards more fuel efficient and with less impact on the environment.

Electronics

The trend is the miniaturization of electronics and, therefore, requires more and more complex and accurate components. Our CNC machining services in China offer the precision necessary for crafting small, complex parts that meet the tech industry’s needs.

From connectors to housings to circuit board components, this website provides solutions that meet up with the dynamism of this industry.

Medical

In many instances, the medical device and equipment call for elements that have close tolerances. CNC machining of these parts is the most effective and precise due to their critical applications. At TheDieCasting.com, we proudly support the healthcare industry with reliable precision machining solutions.

This is how TheDieCasting.com keeps its operations sustainable.

Environmental responsibility was considered the value that lies in the foundation of the company’s work. As a responsible CNC machining parts manufacturer, we strive to minimize waste and energy consumption without compromising quality. Our high-speed machining processes are optimized to reduce material usage and environmental impact, helping our clients achieve their sustainability goals.

Also, we always seek new opportunities to improve performance, from reusing and recycling materials to applying energy efficiency technologies in our buildings.

The Future of CNC Machining

The outlook for the CNC machining industry is positive because new technology developments are constantly being made and there is increasing demand for better quality manufacturing solutions. Advanced solutions such as 5-axis machining, Artificial Intelligence integration, as well as automatization will shape the industry shortly. At TheDieCasting.com, we’re excited to be at the forefront of these changes, delivering cutting-edge precision machining solutions that exceed expectations.

We also expect greater Industry 4.0 maturity, where connected production systems and data insights will improve production lines further. These developments are a result of relying on faster, more precise, and cost-effective solutions to clients all over the world.

Partner with TheDieCasting.com for Superior CNC Machining Services

In a world where precision, speed, and quality are paramount, TheDieCasting.com stands out as a premier provider of CNC machining services in China. Whether you need custom components or large-scale production, our expertise as a trusted CNC machining service manufacturer ensures that your needs are met with excellence.

When you decide to work with us, that is not only hiring a service provider but a team with your best interest in mind. From high-speed machining to bespoke precision machining solutions, we’re here to turn your ideas into reality.

Are you all set for the advanced level of your manufacturing procedure? Contact TheDieCasting.com today and discover how our world-class CNC machining services can transform your business.

FAQs

1. What industries benefit the most from CNC machining services?

CNC machining is applicable in several industries because of its awareness and sharpness in the marketplace. Our services are divided into several categories, mainly the aerospace, automotive, electronics, medical, and industrial equipment industries, which can be found at TheDieCasting.com. For instance, the aerospace industry needs high-strengthening elements such as turbine blades and structure parts that call for close tolerance that can be effectively produced with the help of CNC Machines.

Likewise, the automobile industry has great uses for this process, as engine parts and custom accessories require CNC machining for durability and precision. The electronics industries use CNC machining for small parts such as connectors and housing because small objects require higher precision for manufacturing complex appliances. The instruments used for surgery, artificial joints, and diagnostic products in medical research should be highly accurate. Durability enforces resistant materials that also apply to industrial equipment, and these CNC machining can realize. These industries believe in CNC technology as it allows the generation of parts with optimum efficiency and safety.

2. Which materials can be used for CNC machining?

CNC machining can accommodate a variety of materials, which means manufacturers will find it a convenient option. Here at TheDieCasting.com, we deal with a lot of metal, plastic, and composite materials. For instance, aluminum, stainless steel, titanium, brass, and copper, among others, are often chosen for strength/ durability. Organic materials like ABS, Nylon, Polycarbonate, and PEEK are ideal enclosures when factors like low weight and corrosion resistance play an important role. Also, composites such as CFRP are suitable as several industries demand the best quality parts from lightweight materials with superior strength. The team at The Novo Wire Company offers each customer consultancy services in choosing the appropriate material for a given undertaking occasioned by traits like strength, weight, cost, and utility.

3. What is the average response time for CNC machining projects?

The lead time in producing CNC machining projects is also influenced by issues to do with complexity, the quantity of parts that are to be produced, and material type. Like any good die-casting company here at TheDieCasting.com, a fast turnaround time is important without sacrificing quality. In the initial stages, normally, design and planning happen; here, we look at the client’s design for manufacturing and then agree on the price to be charged. This stage normally lasts a couple of days.

After that, there is approval for production to start. Small runs of prototypes may take a couple of days, and larger production runs may take a few weeks, depending on the extent of the project requirement. As we mentioned earlier, after manufacturing, each part is subjected to various quality control checks to meet the client’s requirements before dispatch. Through this, we are always open and give clients an accurate period to complete their projects, thus keeping them attending to their plans effectively.

4. How TheDieCasting.com controls the quality of the CNC machined parts?

The Die Casting Website maintains quality as its core business value. Our precision machining solutions are supported by a comprehensive quality assurance process that involves multiple stages. This technique ensures the accuracy of dimensions and tolerance on the respective part where advanced metrology tools, including the CMMs, are used. We also conduct material tests to confirm that they satisfy the required strength, durability, and performance standards.

Also, the performance of our machining processes is continuously supervised with the help of automated systems for the following purposes: identification of deviations from the required parameters and correction of these deviations in real time. Each subassembly and component is inspected for conformance with the client’s precise requirements before the product is claimed to be ready for delivery. These meticulous measures ensure that our CNC machining services consistently deliver parts of superior quality.

5. What does distinguish TheDieCasting.com from other providers of CNC machining services?

TheDieCasting.com has a competitive advantage of exceptionalism from professionalism, cutting-edge technology applications, and proprietory client attention. With years of experience in the industry, we have built a reputation as a reliable CNC machining service manufacturer capable of handling complex and demanding projects. Our investment in advanced high-speed machining equipment ensures that we stay ahead of industry trends and deliver exceptional results.

Unlike many providers, we adopt a highly collaborative approach, working closely with our clients to understand their unique needs and provide tailored precision machining solutions. From advising on material choice to arriving at the best design solutions for production, we spare no effort to satisfy our clients. Furthermore, our ability to provide efficient and cost-effective CNC machining services in China positions us as a preferred partner for businesses worldwide. Signifying, we integrate technical capability with quality and innovation to deliver more than our promise to clients.