Table of Contents

ToggleEngineering

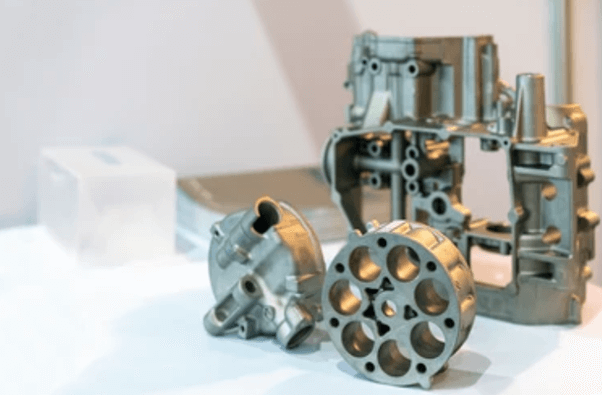

We not only satisfy your demands as your supplier but also we energetically look for methods to optimize your part design therefore save your cost and time during long period massive producing. We have good quality management techniques that are so successful.

We analyze, improve and completely finish any existing tooling issue may have that is not reaching your demands and specifications. As the best die casting manufacturer we put a new management system on the issue and get solutions on what we will improve to solve the issue. We always listen to you, our customers. We do not just classify your problem into a pre-set mould solution. We input time to learn your business requirements, your difficulties and your production demands, after that we suggest a solution to the issues.

Good engineering is the start and the only guarantee of success for any project in die casting parts.Whether a customer never ordered a die casting before or has used many die castings over many years before, a thorough consultation with a die caster before a project is started is a must, benefits both sides and prevents much heartache later on.

We have learned to listen thoroughly to the customer and then give our ideas and make our proposals.

Our engineers have both long experience in the field and keep up to date on all research by academic and National organizations in the die casting field and apply them.

We use the most current editions of CAD software and are able to receive and process customer engineering inputs from Autocad, UG, PRO-E and others.We never close the doors on new revisions a customer may suggest even after tool construction has begun. After all, our ultimate goal is product useful to its user.

Injection Mold Price

Unlock High-Performance, Cost-Effective Solutions for Your Injection Molds