Zinc die casting is the ideal metal for die casting. Its characteristics of easy flow and low-temperature melt enable casting complex shapes easily, make very thin walls that are strong nonetheless, and keep using one set of tools practically forever.

Add to this its outstanding corrosion resistance, the capability to polish and plate to a high luster or any artistic finish and its relatively low cost of casting and you see why it is so ideal.

Zinc Die Casting Manufacturer

We are zinc die casting manufacturer in China that could offer die casting parts of Zamak 3 or Zamak 5, Zamak alloy from a fraction of 3 gram to 2kg. for many industries. We have customer dies in use 10, 15, 20 years that yield excellent zinc die casting parts. We can do the same for you.

If you are searching for zinc die castings services from China zinc alloy die casting parts manufacturers, from a few grams. to several kilograms, in large quantities or small lots, cast and trimmed with surface finish, and completely ready to assemble into the most demanding zinc die casting product, look no more.

We have been around since 2001, serving industries from the precision demanding aerospace and military to the cost-conscious hardware and housewares, with a roster of customers who stayed loyal to us for decades.

Our Zinc Die Casting product is good in quality and competitive in price. We are the manufacturer and supplier of Zinc Die Casting following your specific requirement. We are looking forward to your E-mail and for establishing a cooperative relationship with you.

Zinc Die Casting Manufacuring in China

We will provide professional Zamak alloy Die Casting & surface finishing with good services. If you are looking for other types of die casting, please go to aluminum die casting and magnesium die casting to get more information.

You are welcome to send us your requirements for a zinc alloy die casting quotation.

What is zinc die casting

Zinc dies casting is one of the most effective and adaptable high-generation techniques utilized for assembling solid, exact, and complex metal parts. With regard to zinc die casting, there are two fundamental families. The regular or ZAMAK alloys, which are normally named dependent on their successive improvement.

These incorporate Zamak Alloy 3,Zamak Alloy 5, and zinc Alloy 7. At that point, there are the zinc alloys with higher measures of aluminium than the traditional alloys, ZA. These incorporate ZA-8, ZA-12, and ZA-27. ZA alloys offer higher quality and valuable bearing properties.

The Die Casting process started with the utilization of the alloys tin and lead, magnesium and copper alloys immediately pursued, and by the 1930s, huge numbers of the cutting edge alloys still being used today got accessible.

The process advanced from the low weight infusion casting to a cutting edge high weight infusion of 4500 pounds for each square inch. The cutting edge processes are fit for creating high trustworthiness, net casting shape with phenomenal completion surfaces.

The Sort Of Zinc Die Casting Material

There are two fundamental groups of zinc casting alloys: ZAMAK alloys and ZA alloys. Zamak alloys contain around 4% aluminium and give astounding die castability and great quality. The ZA alloys contain higher measures of aluminum and offer prevalent quality. Both offer the capacity to cast with the mind-boggling point of interest and close dimensional resiliences at high creation rates.

In these two types of zinc casting alloys. The traditional or ‘ZAMAK’ alloys are ordinarily named dependent on their successive advancement, went before by the word alloy. These incorporate Alloy 2, Alloy 3, Alloy 5, and Alloy 7. The latest expansion to the ZAMAK family is the new high-ease or ‘HF’ alloy.

Zinc alloys with higher measures of aluminum than the traditional alloys utilize the prefix ZA pursued by their rough aluminum content. These incorporate ZA-8, ZA-12, and ZA-27. ZA alloys offer higher quality and helpful bearing properties.

Here are the focal points and inconveniences of zinc alloy die casting parts, and we likewise list the applications reasonable for them.

Advantages of Zinc die casting parts:

- Zinc alloy die casting parts have more noteworthy relative weight.

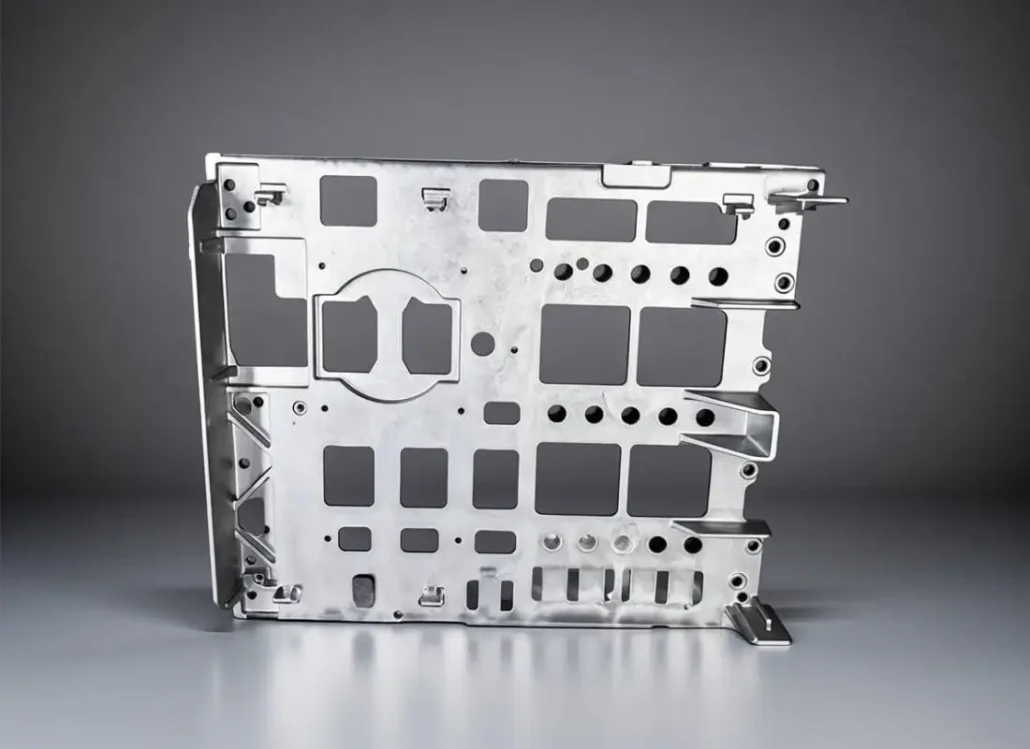

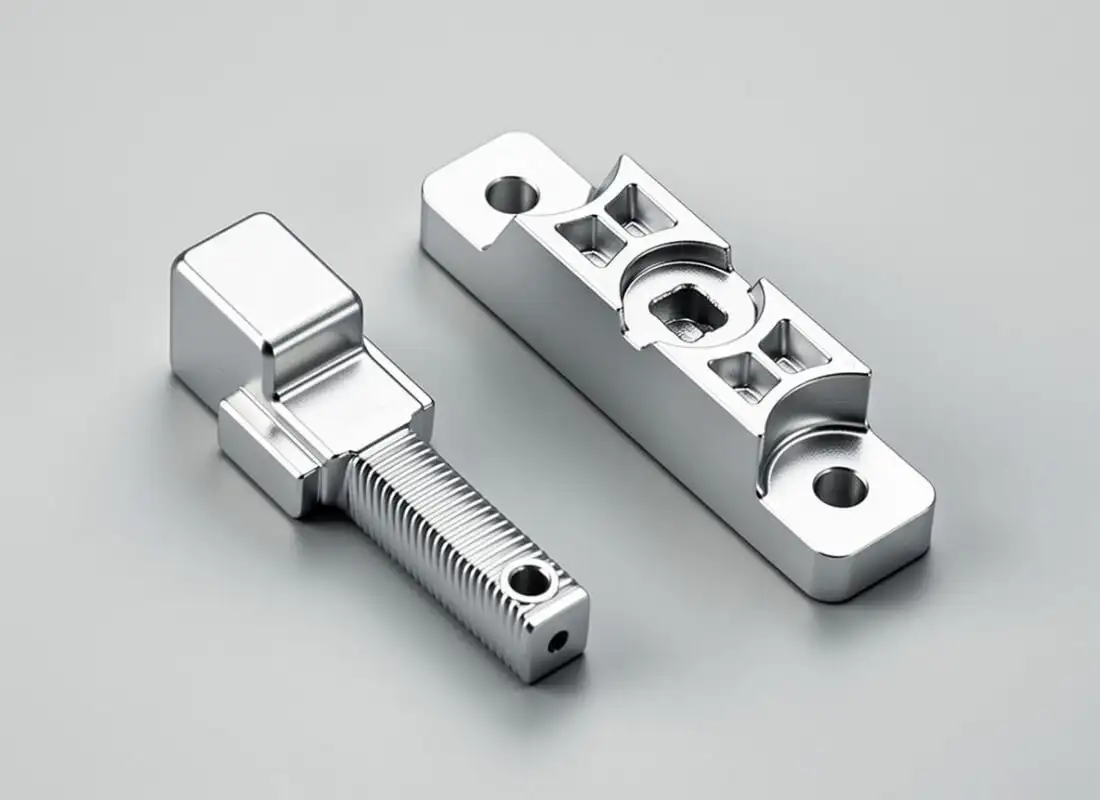

- Zinc alloy die casting exact parts have complex shapes, more slender dividers, and smooth surfaces.

- Zinc alloy die casting parts have great accuracy, high mechanical quality, reflexive and conservative surface. Little or no cuttings happens during the machining process.

- Zinc alloy die casting parts have a few surface medications: electro-plating, splashing, painting, cleaning, pounding and so forth.

- Zinc alloy has no iron assimilation, no profiling erosion, no shape adherence when softening and casting.

- Zinc die casting parts have great mechanical properties and scraped area execution.

- A low dissolving point around 385℃ permits the simple forming of zinc alloy dies casting.

Disadvantages of zinc die casting parts

- Bad corrosion resistance. At the point when the accidental components of lead, cadmium, and tin which have low dissolvability in zinc alloy surpass norms, the zinc alloy casting parts will endure volume swell, malleability diminishes and far and away more terrible: they can be broken. Intergranular electrochemical erosion causes the maturing and twisting of zinc alloy die casting parts.

- Zinc alloy die casting parts are not permitted to be utilized both in high temperature and low temperature (beneath 0℃). In high temperature, the rigidity of the zinc alloy die casting parts will decrease astoundingly and in low-temperature sway properties and will have an extraordinary tumble off.

Zamak die casting Process, Appliiances VS other casting

Zinc alloy Die casting is one of the most broadly utilized pieces of die casting alloys, it offers high exactness just as low tooling expenses. Zinc die casting has an expansive scope of points of interest and can be applied in different places because of its astounding exhibition and quality.

The Zinc Die Casting Process

The zinc dies casting process is done in a programmed machine appropriate to withstand the high weight. The liquid metal is pushed into two-piece steel die containing at least one cavities, each a precise opposite imitation of the part or parts. the mechanical properties of weight zinc die castings are commonly better than other casting processes on account of the brisk chill and quick hardening that happens when the liquid metal comes into contact with the moderately cool steel side.

The Application of Zinc Die Casting

For the extra parts with complex geometry, the zinc die casting process is utilized dependent on a few points of interest, for example, a once-shaped example, Plating zinc alloy jewelry, straightforward machining innovation, high generation proficiency, and material sparing. At the interim, Zinc alloy die casting has a far-reaching application in the national guard, traffic, gadgets, development, day by day equipment and particularly car industry.

Zinc Die Casting VS Another Casting

Zinc alloys rival different materials in the die casting industry: aluminum, cast iron, machined metal, machined steel, and magnesium, together with zinc, are the most generally utilized metal in die-casting items. Picking alloys is an intense activity: the die caster needs to break down the application, material thickness, rigidity, yield quality, liquefying temperature and flexibility to get a superior result with all its practical and aesthetical necessities.

Zinc alloys vs Aluminium die casting

One of the primary distinctions among aluminium and zinc alloys is zinc low dissolving temperature and its requirement for lower pressure during die casting. Thus zinc alloys are the most castable ones. Having a low softening temperature permits zinc die casting apparatuses to last more, and since dies are costly, utilizing them for a more drawn out time is a financially savvy way to deal with a high volume of generation.

Also, zinc can be thrown with HPDC, which is more affordable than the cold chamber process; by utilizing HPDC it is conceivable to speed up. Aluminum alloys, then again, are typically thrown with a cold chamber system, which is less gainful than the hot chamber process utilized for zinc.

Zinc alloy vs magnesium die castings

One of the fundamental contrasts among magnesium and zinc alloys is that zinc alloys need lower weight and temperature for casting. In contrast to magnesium, which requires an extraordinary treatment for consumption obstruction and completing, zinc alloys have great erosion opposition and a superior surface just in the wake of being launched out from the die.

Magnesium has a truly low thickness and, much the same as zinc, magnesium alloys can be die thrown utilizing HPDC: therefore, they have quicker process durations than aluminum. Lean more about our Magnesium die casting services.

Zinc alloys vs machined metal parts

Zinc alloys have lower process costs, lower material costs, less process scrap and proportional or prevalent resistances reachable than machined metal. As in the past, the term metal respects a wide scope of cast materials, with various mechanical properties and it is difficult to characterize every one of them.

How To Buy Good Quality Zinc Die Casting Parts.

Picking how to purchase great quality, in a wide scope of China zinc alloy die casting companies is an intense issue. Having the correct accomplice arrives at arranging and undertaking objectives and can be helpful to build up an item or segment in a co-structure movement, while a terrible accomplice could be a hard snag to get the objectives.

For choosing on the most proficient method to purchase great quality zinc die castings you to need to consider 5 significant perspectives, for example,

Co-structure service; Quality of the product; Delivery on time; Shape structure; Cost viability

The correct supplier among zinc die casting manufacturers?

The initial step for an originator is the choice of creative innovation. Die-casting processes offer the chance to make each sort of items, and to satisfy specialized or aesthetical necessities, sparing expenses simultaneously.

Why Zinc Die Casting

In zinc die-casting, originators can make creative shapes in view of the specific capacity of the material to permit slender resistances. They can likewise furnish the clients with a part which reacts to auxiliary needs, helps to lessen costs, conveyance time and material waste.

When the originators have settled on their choice, they have to know the material responses, and working with the supplier in a co-structure stage can help them improve processes and results.

Co-design Service

In the event that you don’t consider the whole creation process, it could debilitate the item or segment execution and capacity.

Zinc die casting manufacturers ought to have a building office completely committed to investigation and reproduction assignments, so as to ensure the best help to their costumers during the item configuration stage.

The ideal supplier ought to likewise have the likelihood to do quick prototyping inside its structure, straightforwardly utilizing a pilot instrument, with no need of sub-temporary workers for the testing tasks.

Quality of product

Limiting dangers is one of the primary qualities of a decent zinc die casting manufacturer. The supplier ought to have the ability to design and predict any conceivable issue and hazard identified with the entire process. FMEA and other measurement instruments and devices must be utilized to plan the process. State-of-the-art machines, gadgets, and robots for a legitimate robotization level add to arrive at the client’s desire, for example, item quality and on-time conveyance.

Time delivery

Zinc die caster realizes that planning and the capacity to comply with a time constraint are carefully identified with the generation plan so as to arrive at the client’s desires. To hit the objective the ideal supplier ought to think about 3 viewpoints: basic leadership processes, thought of response and cooperation between divisions.

Basic leadership processes

Quick basic leadership processes enable an organization to be progressively aggressive and carefully centered around objectives. On account of a streamlined administration structure, the choices will be faster: that means an advantage for customers in terms of reaction to a new project or challenge.

We are the leading zinc die casting manufacturer in China! We specialize in providing custom zinc die casting services to meet the unique needs of our clients. Our expert team can assist you in designing and producing high-quality zinc die casting products, with a focus on precision, durability, and aesthetic appeal.

Our zinc die casting manufacturer service Zamak 3 and Zamak 5 ally die casting parts with production of complex shapes and tight tolerances, giving our clients the freedom to create unique products that stand out in the market. We utilize cutting-edge technology and techniques to ensure that our products meet the highest standards of quality, while also ensuring a smooth and polished surface finish.

Our team takes great pride in the level of customer service we provide to our clients. We work closely with our customers to ensure that their exact specifications are met, and we offer fast turnaround times to ensure that your completed products are delivered on time and on budget.

With years of experience in the zinc die casting industry, our zinc die casting company has developed a reputation for delivering high-quality products that meet our customers’ needs and exceed their expectations. Our team is dedicated to providing the best possible service to our customers, and we are committed to building long-term relationships with each of our clients.

Thank you for considering our China zinc die casting company. Please contact us to discuss your unique product needs, and we will be more than happy to assist you with your project.

FAQs

What zinc alloys are used for zinc die casting products?

There are many type of zinc alloys can be used for zinc die casting process:

Zamak 3 (ZNAl4 / ZDC2): The most widely used alloy, accounting for over 70% of die-cast parts. It possesses excellent mechanical properties, good fluidity, and good electroplating and painting performance.

Zamak 5 (ZNAl4Cu1 / ZDC1): Contains more copper (~1%) than Zamak 3, resulting in higher strength, but slightly lower ductility.

Zamak 7: A high-fluidity alloy with a lower magnesium content, offering better surface finish and superior ductility.

ZA-8 (High-Aluminum Zinc Alloy): With a higher aluminum content (~8%), it offers better creep resistance and strength, suitable for lightly loaded but structurally demanding components.

EZAC: A high-strength zinc alloy with excellent creep resistance, suitable for demanding engineering components.

How long is taking to make a zinc die casting product?

The timeline for designing and manufacturing a die-casting part depends on several factors, including the design’s complexity, the casting geomitry and size, In most other cases, completing it can take between 5-6weeks to get first sample of zinc die casting parts.

At CNM Casting, the timeline starts with a consultation with you to identify your requirements. The first step is to design the zinc casting, if you already have casting design, then that will be more easy for us, we will design the zinc die casting tool using the state-of-the-art computer-aided design program. Our design team then produces a manufacturing plan for zinc die casting tooling manufacturing. After the tooling manufaturing has been finalized, then we will test the mold and make some casting sample and send to our customer for approval. We also keep our clients informed during the tooling manufacturing stage.

What are the main advantages of using zinc die casting parts?

There are many advantages of using zmak die casting products. listed as below:

- Zinc alloy die casting parts have more noteworthy relative weight.

- Zinc alloy die casting exact parts have complex shapes, more slender dividers, and smooth surfaces.

- Zinc alloy die casting parts have great accuracy, high mechanical quality, reflexive and conservative surface. Little or no cuttings happens during the machining process.

- Zinc alloy die casting parts have a few surface medications: electro-plating, splashing, painting, cleaning, pounding and so forth.

- Zinc alloy has no iron assimilation, no profiling erosion, no shape adherence when softening and casting.

- Zinc die casting parts have great mechanical properties and scraped area execution.

- A low dissolving point around 385℃ permits the simple forming of zinc alloy dies casting.

How do you ensure the quality and longevity of die-casting molds?

To make high quality zinc die casting products requires a comprehensive approach, focusing on optimized part design, mold manufacturing and final inspection, such as:

- Uniform Wall Thickness: Design with uniform wall thickness to prevent porosity, warping, and shrinking.

- Draft Angles and Radii: Use appropriate draft angles for easy ejection and replace sharp corners with rounded edges to reduce stress concentrations.

- Mold Design and Manufacturing: Ensure proper venting, cooling channels, and overflow systems to prevent air entrapment and defects. Mkae sure using high quality steel for the tooling, and use high precision equipment to manufacture the zinc die casting tool

- First Article Inspection (FAI): Generate a FAI report for critical dimensions and features.

- Dimensional Accuracy: Use Coordinate Measuring Machines (CMM) and calipers to verify precise geometries.

- Visual Inspection and Packing: Check for flash, surface,and cosmetic defects. After that using good packing material carefully pack the zinc die casting products and ready for delivery.