Magnesium Die Casting

Magnesium die casting is a process in which the molten metal is forced to press under high pressure into the mould cavity using magnesium alloys. High pressure Die casting is one of the best technique widely used to create inexpensive metal parts for a variety of applications, especially magnesium casting products. The metal hardens to get the desired shape.

Magnesium is an excellent choice of die casting to distinguish between durable and durable products, providing a perfect combination of lightness, hardness and corrosion resistance to various casting applications. From concept to completion, with. Magnesium is also 100% recyclable, making it an attractive option when looking at the environment. Once the casting tool or die casting component reaches the end of its life, it can be easily recycled to serve a different purpose, thus saving costs and environmental impacts.

Magnesium is the lightest of all structural metals and is widely used in applications that require high-performance properties. In addition, the magnesium mass is almost equal to many plastics and has many advantages over plastics, including excellent toughness and corrosion resistance. The magnesium parts can be poured in a clean form and have a high ratio of strength to weight. Magnesium die casting can also be used in high-temperature applications

Magnesium is lightweight and has a strong structure for some casting components. Replacing magnesium components instead of heavy aluminium die casting products can help reduce fuel costs in vehicles where car manufacturers develop new techniques to use the unique properties of magnesium.

Injection Mold Price

Unlock High-Performance, Cost-Effective Solutions for Your Injection Molds

Get a Quote

Advantages of magnesium die casting

There are numerous advantages to die casting part made in magnesium. Magnesium is not only the lightest in all structured materials, but it has excellent rigidity and strong weighting factors. In addition, it has distinct security properties, ideally suited for connectors and electrical buildings.

It has a low melting point

The low melting point makes magnesium much faster and energy efficient to melt without sacrificing the strength of the metal. Low temperature also provides faster cooling. The melting of magnesium is slightly higher than the usual aluminium alloy, making it very compatible with casting projects.

High dimensional accuracy and stability

The best strength/weight ratio for magnesium metal commonly used. Excellent dimensional stability, as well as high impact resistance and dent. The exceptional hydration capacity and low rigidity make it ideal for parts that undergo frequent and sudden changes in direction. High purity alloys can provide the latest best resistance to corrosion of carbon, steel and some aluminium alloys.

High electrical and thermal conductivity

Low heat content means that it requires less energy to reach the casting temperature, and castings are cooled more quickly so that the cycle time is faster. Low temperatures and low intimacy of iron reduce the impact of heat fatigue and corrosion on moulds so that they last longer.

Exceptional thin wall capability

Thin-walled die casting means systems can be manufactured as a single piece, rather than assembled from several components. This simplifies design, reduces assembly costs, improves reliability, reduces the cost of tools and reduces joints, clamps, and welds.

disadvantages of magnesium die casting

Special treatment methods and coatings are essential in determining the application of magnesium casting this is because Magnesium contains impurities, which means that the metal must be cleaned before pouring to remove impurities from the finished product.

Magnesium consumes a large amount of heat in solubility in preparation for die casting, The casting temperature, magnesium provides a much shorter lifespan than other alloys, which can increase production costs.

Since magnesium is easy to get fired, the magnesium dust of accessories in the workshop sometimes leads to initial blasting and fired, so there must be complete ventilation equipment in the processing workshop, including fine equipment such as dust collectors. Control the ignition source, fire prevention measures is the number one important thing when working with magnesium alloys.

CNM TECH has rich experience in producing magnesium alloy die casting parts, we have fully controlled safety systems to produce magnesium die casting parts, contact us to get a price for your project.

Magnesium die casting is a process in which the molten metal is forced to press under high pressure into the mould cavity using magnesium alloys. High pressure Die casting is one of the best technique widely used to create inexpensive metal parts for a variety of applications, especially magnesium casting products. The metal hardens to get the desired shape.

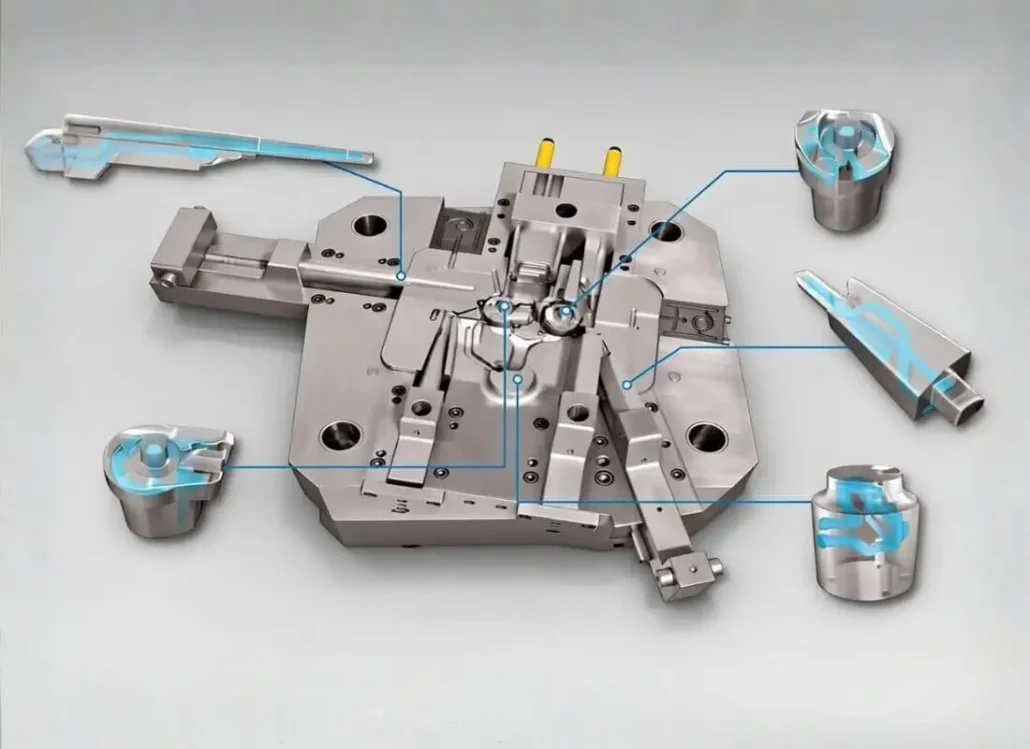

What is Die Casting Mold?

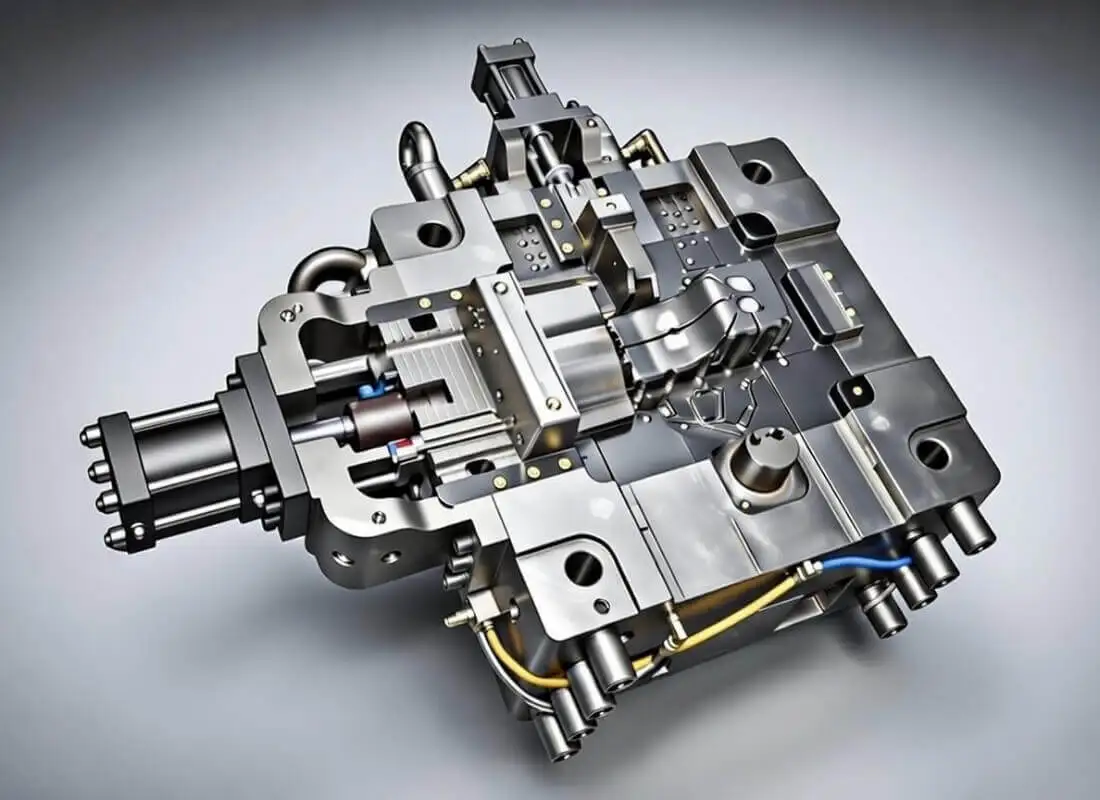

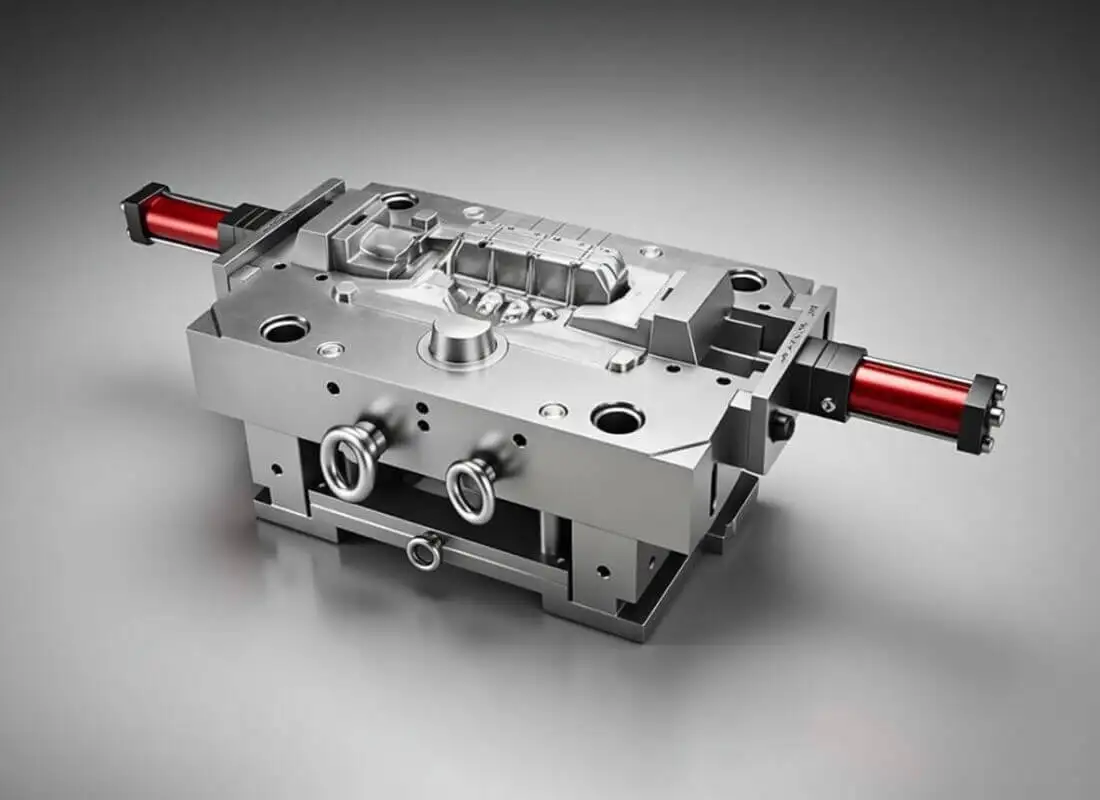

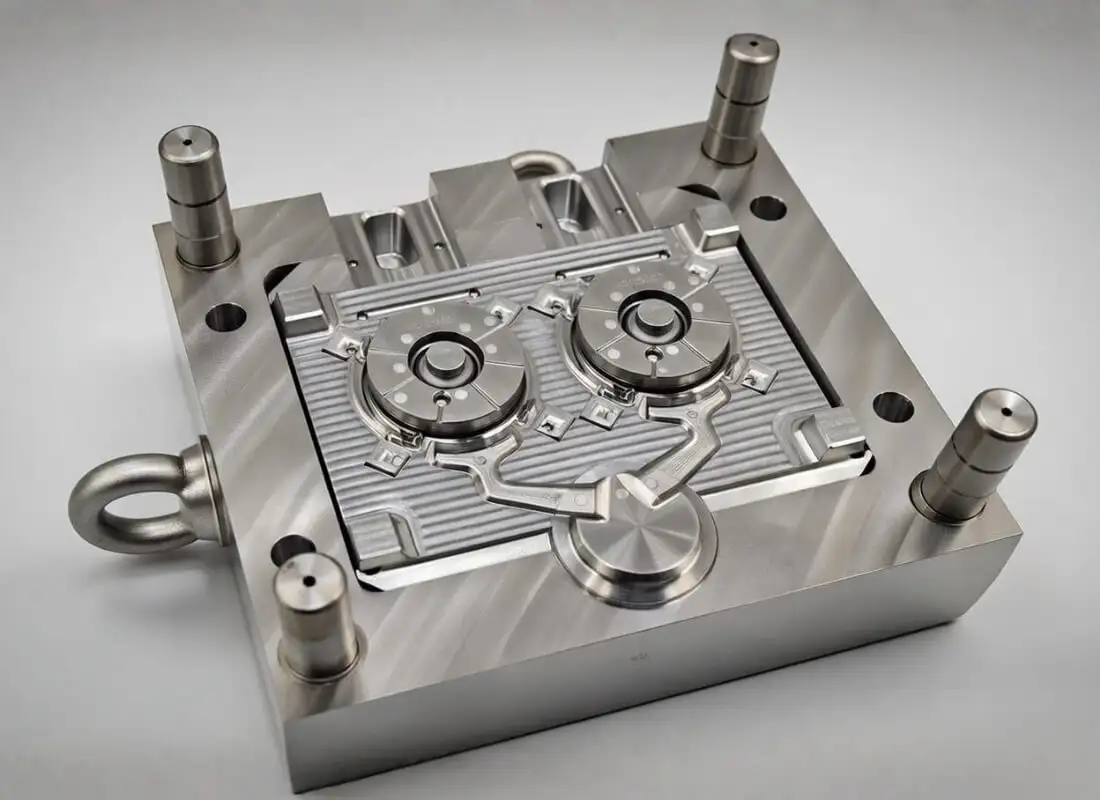

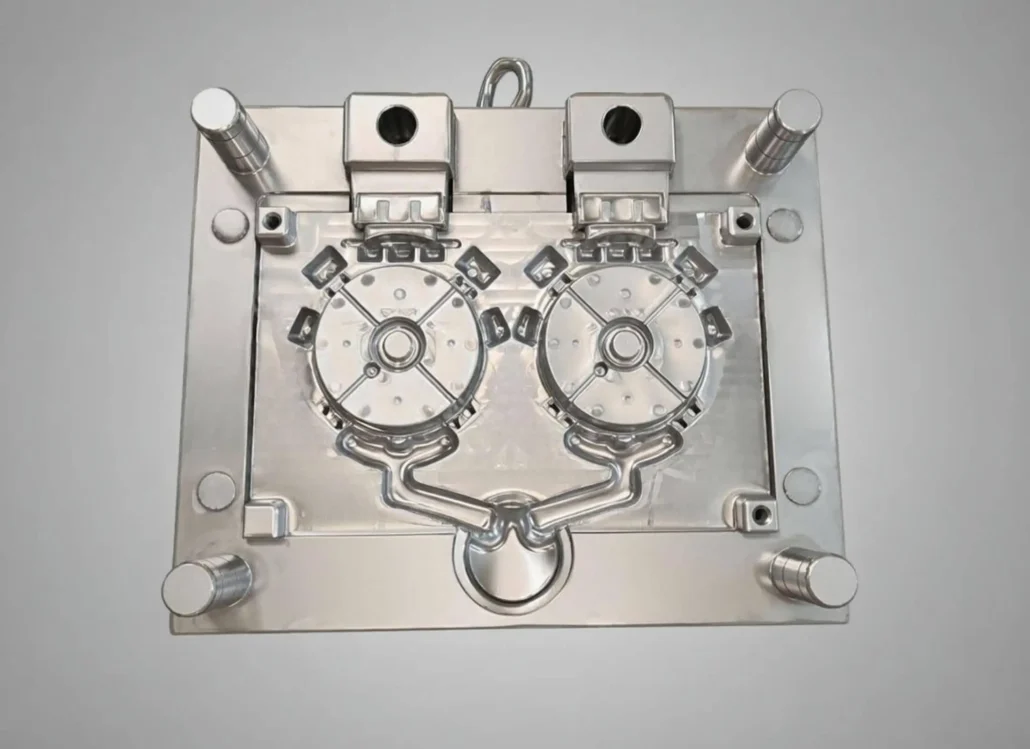

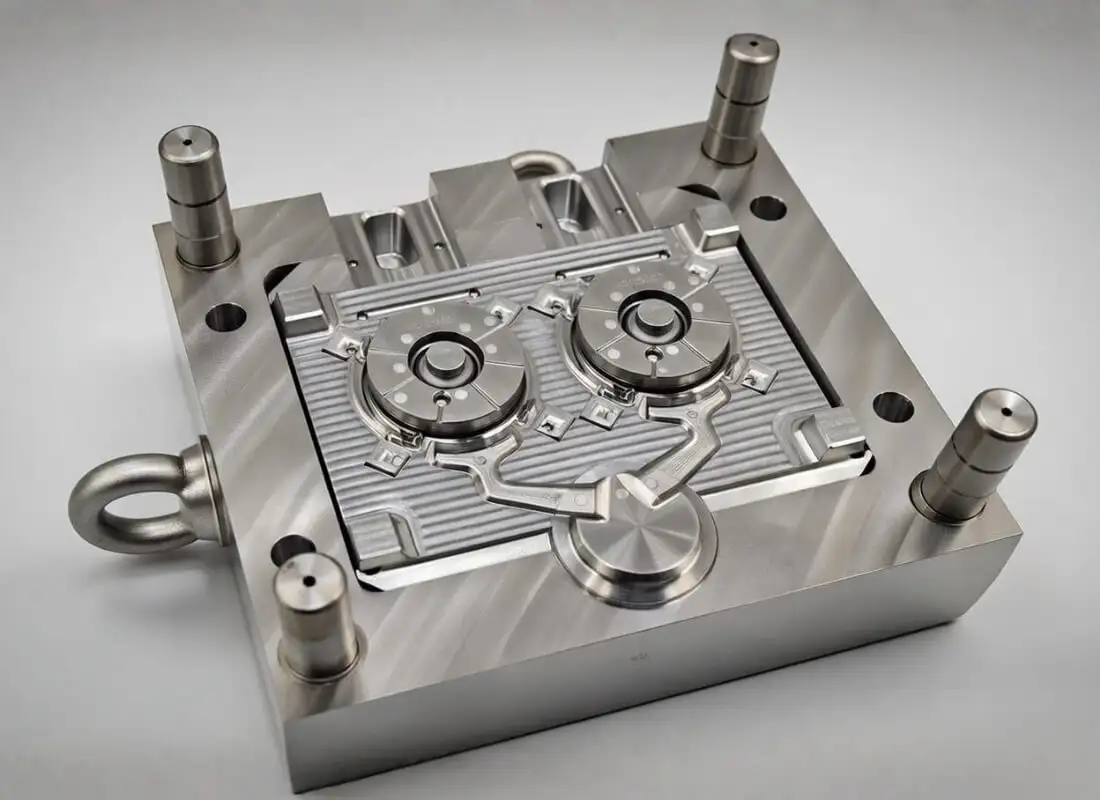

A die-casting mold is a custom-designed tool used in the die-casting process to shape molten metal into precise components. This mold can be constructed from two halves; and are referred to as the cavity and the core, both of which are specifically designed and developed to actualize the desired shape of the production. Due to the application of high pressure, the molten metal fills the mold cavity and creates a highly accurate and fine surface finish for the developed parts.

At TheDieCasting.com, our expertise as a die-casting tooling manufacturer enables us to craft molds that are tailored to meet the specific requirements of diverse industries. Our molds play a key role in the advancement and production process in automotive, consumer electronics, and various other sectors.

What is Magnesium Die Casting ?

Magnesium die casting is a process in which the molten metal is forced to press under high pressure into the mould cavity using magnesium alloys. High pressure Die casting is one of the best technique widely used to create inexpensive metal parts for a variety of applications, especially magnesium casting products. The metal hardens to get the desired shape.

Magnesium is an excellent choice of die casting to distinguish between durable and durable products, providing a perfect combination of lightness, hardness and corrosion resistance to various casting applications. From concept to completion, with. Magnesium is also 100% recyclable, making it an attractive option when looking at the environment. Once the casting tool or die casting component reaches the end of its life, it can be easily recycled to serve a different purpose, thus saving costs and environmental impacts.

Magnesium is the lightest of all structural metals and is widely used in applications that require high-performance properties. In addition, the magnesium mass is almost equal to many plastics and has many advantages over plastics, including excellent toughness and corrosion resistance. The magnesium parts can be poured in a clean form and have a high ratio of strength to weight. Magnesium die casting can also be used in high-temperature applications

Magnesium is lightweight and has a strong structure for some casting components. Replacing magnesium components instead of heavy aluminium die casting products can help reduce fuel costs in vehicles where car manufacturers develop new techniques to use the unique properties of magnesium.

Table of Contents

ToggleInjection Mold Price

Advantages of magnesium die casting

There are numerous advantages to die casting part made in magnesium. Magnesium is not only the lightest in all structured materials, but it has excellent rigidity and strong weighting factors. In addition, it has distinct security properties, ideally suited for connectors and electrical buildings.

It has a low melting point

The low melting point makes magnesium much faster and energy efficient to melt without sacrificing the strength of the metal. Low temperature also provides faster cooling. The melting of magnesium is slightly higher than the usual aluminium alloy, making it very compatible with casting projects.

High dimensional accuracy and stability

The best strength/weight ratio for magnesium metal commonly used. Excellent dimensional stability, as well as high impact resistance and dent. The exceptional hydration capacity and low rigidity make it ideal for parts that undergo frequent and sudden changes in direction. High purity alloys can provide the latest best resistance to corrosion of carbon, steel and some aluminium alloys.

High electrical and thermal conductivity

Low heat content means that it requires less energy to reach the casting temperature, and castings are cooled more quickly so that the cycle time is faster. Low temperatures and low intimacy of iron reduce the impact of heat fatigue and corrosion on moulds so that they last longer.

Exceptional thin wall capability

Thin-walled die casting means systems can be manufactured as a single piece, rather than assembled from several components. This simplifies design, reduces assembly costs, improves reliability, reduces the cost of tools and reduces joints, clamps, and welds.

disadvantages of magnesium die casting

Special treatment methods and coatings are essential in determining the application of magnesium casting this is because Magnesium contains impurities, which means that the metal must be cleaned before pouring to remove impurities from the finished product.

Magnesium consumes a large amount of heat in solubility in preparation for die casting, The casting temperature, magnesium provides a much shorter lifespan than other alloys, which can increase production costs.

Since magnesium is easy to get fired, the magnesium dust of accessories in the workshop sometimes leads to initial blasting and fired, so there must be complete ventilation equipment in the processing workshop, including fine equipment such as dust collectors. Control the ignition source, fire prevention measures is the number one important thing when working with magnesium alloys.

CNM TECH has rich experience in producing magnesium alloy die casting parts, we have fully controlled safety systems to produce magnesium die casting parts, contact us to get a price for your project.

Design and Engineering

The process starts by undertaking consultations with our clients to understand them. There is professional software, which our design team utilizes to generate detailed sketches of the mold. Whether a complex high pressure die casting tooling design or a straightforward aluminum die casting mold, we ensure the design is optimized for efficiency and durability.

General Die Casting Tooling

General die casting tooling includes molds and related tools for applications that do not require the extreme pressures of high-pressure systems. These tools are mainly applied in small-scale machining or when dealing with part of simple shapes. As an experienced die casting tooling manufacturer, we understand the nuances of high-pressure and general tooling, ensuring our clients receive solutions that match their specific requirements.

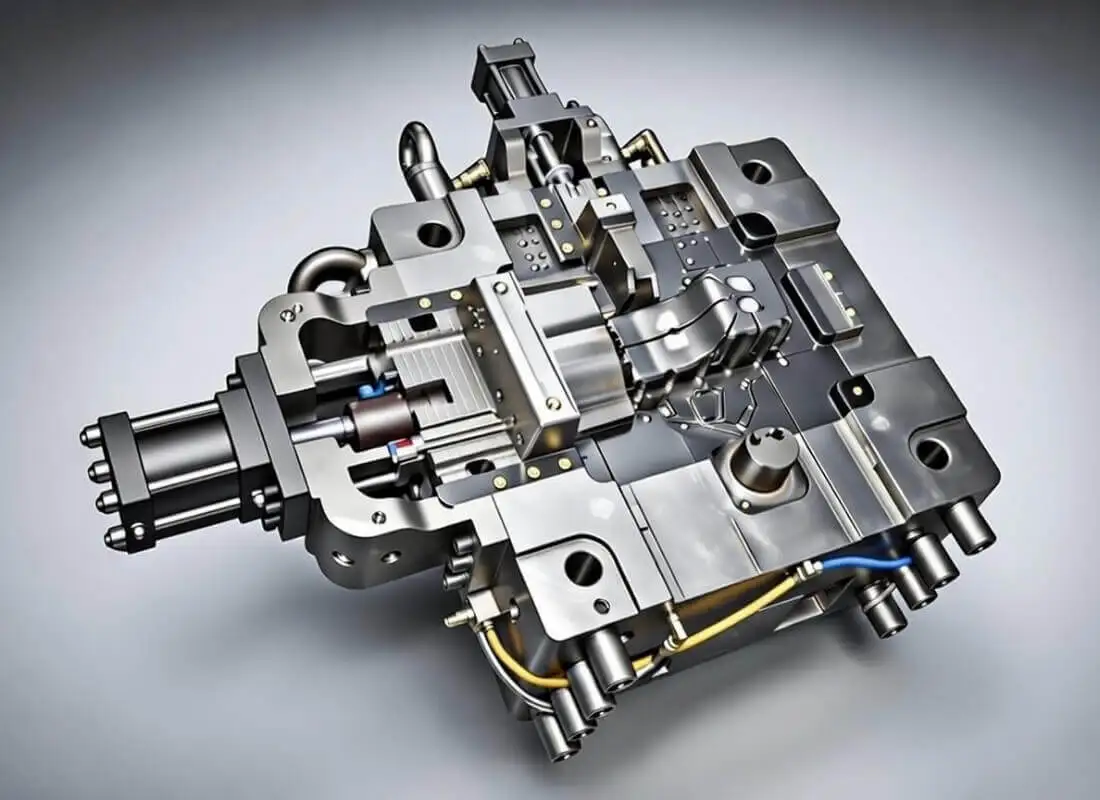

The Process of Die Casting Mold Creation

The creation of a die casting mold is a highly technical process that involves several stages, each demanding meticulous attention to detail. At TheDieCasting.com, we follow a structured approach to ensure the highest quality molds:

Material Selection

Selecting an appropriate material is an important criterion for the container’s efficiency. We then precisely choose materials that can endure the intrinsic pressure and temperature of the operation stage without compromising the structure. This means that every mold that is produced here offers you enduring reliability.

Sustainability in Die Casting Mold Production

TheDieCasting.com follows sustainable business practices as a foundation for the company. We aim to reduce waste and energy use in making molds as much as is practically possible. For instance, our aluminum die-casting molds are designed for efficiency, ensuring optimal material usage and reducing environmental impact.

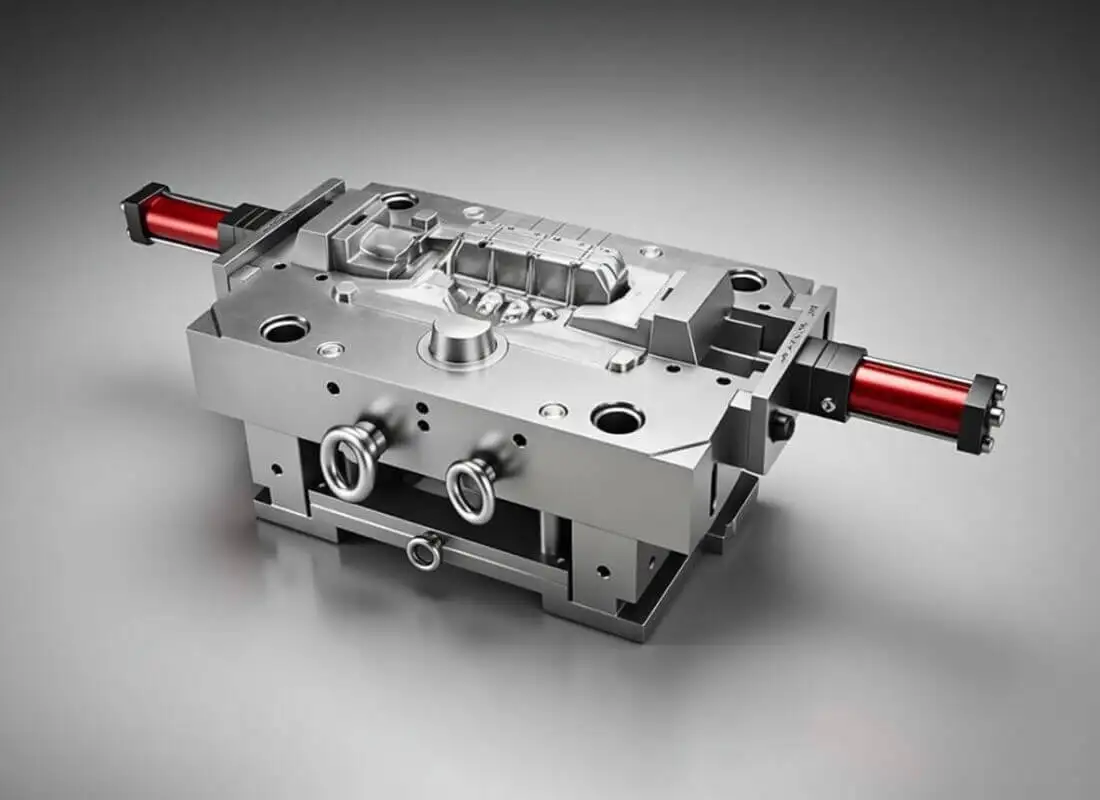

Applications of Die Casting Molds

The versatility of die-casting tooling makes it invaluable across various industries. Our molds at TheDieCasting.com are applied in multiple areas, including automotive, electronics, industrial equipment, and many others.

For example, our aluminum die-casting molds are instrumental in producing lightweight yet robust components like engine blocks, transmission cases, and structural elements in the automotive industry. Similarly, the electronics industry relies on our high pressure die casting tooling to create intricate parts with excellent thermal and electrical conductivity.

Our ability to adapt to the unique demands of each industry is a testament to our expertise as a leading die-casting tooling manufacturer.

Why Choose TheDieCasting.com for Die Casting Molds?

As a trusted die-casting tooling manufacturer, we have built a reputation for excellence through expertise, advanced technology, and client-focused service. At Stereo, our team does not only concentrate mainly on the abilities and skills of the employees but also on delivering the best to meet the client’s expectations.

Our commitment to quality is evident in every mold we produce, whether it’s a complex high pressure die casting tooling solution or a standard die casting tooling design. After years of growth and concentration on improving the company’s capacities, we are a dependable partner for industries on the global level.

The Future of Die-Casting Molds

The die-casting industry has many sub-industries that are mainly driven by new materials, designs, and new technology. To do so, we constantly monitor emerging trends at TheDieCasting.com to provide clients with innovative options. From developing more efficient aluminum die-casting molds to exploring the possibilities of AI-assisted tooling design, we are committed to pushing the boundaries of what’s possible.

As industries continue to demand higher performance and sustainability, our expertise as a leading die-casting mold manufacturer positions us to meet these challenges confidently.

Partner with TheDieCasting.com for Superior Die Casting Molds

Selecting the best partner for your die-casting business today requires more attention than ever. At TheDieCasting.com, we combine technical excellence, innovative design, and exceptional customer service to deliver the best die-casting molds for your business. Whether you need a custom high-pressure or versatile aluminum die-casting mold, we are here to bring your vision to life.

Contact us today to learn more about our die-casting tooling solutions and discover how our expertise as a premier die-casting tooling manufacturer can elevate your manufacturing processes to new heights.

As industries continue to demand higher performance and sustainability, our expertise as a leading die-casting mold manufacturer positions us to meet these challenges confidently.

FAQs

What is the difference between aluminum die-casting molds and high-pressure die-casting molds?

Aluminum die-casting molds are designed to produce parts using aluminum or its alloys. These molds are designed to take advantage of aluminum properties such as lightweight, non-corrosive, and good thermal conductors. They are often used

in the auto industry, aerospace, and electronics, where strength and low weight are necessary.

On the other hand, high-pressure die casting molds are built to handle the rigorous conditions of injecting molten metal into the mold cavity under extremely high pressure. These molds are made for accuracy and can be used to create complex shapes that do not have high tolerances and need low surface roughness. While aluminum die casting molds are a subset of high-pressure molds, the latter category also includes molds for other metals like magnesium and zinc. When it comes to die casting and rapid tooling at TheDieCasting.com, we provide the best of both worlds to meet your needs for each application.

How long does designing and manufacturing a die-casting mold take?

The timeline for designing and manufacturing a die-casting mold depends on several factors, including the design’s complexity, the mold’s size, and the project’s specific requirements. In most other cases, completing it can take between three weeks and three months.

At TheDieCasting.com, the timeline starts with a consultation with you to identify your requirements. The last step in the concept stage is to design our product using the state-of-the-art computer-aided design program. Our design team then produces a manufacturing plan for easy product manufacturing. After the design has been finalized, the company moves into the material procurement and manufacturing stage affording itself modern technology like computer numerically control machining and other technologies. Performance testing then takes place to test the mold to its maximum capabilities. We also keep our clients informed

throughout the process, telling them whenever there are changes within the progress timelines

What are the main advantages of using high-pressure die casting molds?

High-pressure die casting molds offer several significant advantages, making them a preferred choice for modern manufacturing. Its uses include producing complicated and subtle parts that are accurate and repeatable to high levels of precision. The high-pressure system ensures that the molten metal penetrates all the areas in the mold; therefore, the final product has accurate measurement and polished surface.

Another advantage is the efficiency the bamboo structure provides the team. In high-pressure die casting, cycle time is relatively fast, leading to many parts being directly produced within a short duration, well-suited for industries with high requirments. Also, high-pressure molds are good at reducing porosity to enhance the mechanical reliability of the comp. LinkedIn: High-pressure molds ensure the structural strength of the parts since they lessen the porosity level. At TheDieCasting.com, we design and manufacture high-pressure die casting molds to deliver these benefits while maintaining cost-effectiveness and durability.

How do you ensure the quality and longevity of die-casting molds?

As you will see at TheDieCasting.com, quality, and longevity are at the heart of our strategic thinking. We employ tool steel and other grades or alloys to guarantee that our molds can handle the rigorous pressures and temperatures when used with the die-casting process. Our manufacturing involves using technological methods such as Computer Numerical Control machining techniques, which give high accuracy in molds.

Apart from the material quality, there are the testing protocols. Every die casting mold undergoes performance testing under simulated operational conditions to ensure it meets or exceeds client specifications. We also advise on how to maintain the mold well to increase its durability. Employing modern approaches to production in conjunction with extremely high standards for quality assurance, we guarantee that clients obtain molds that would guarantee high performance in long-term production.

What industries benefit most from die-casting molds, and how can TheDieCasting.com help?

Die-casting molds are essential in industries with critical precision, efficiency, and durability. The automotive industry, for example, relies on aluminum die-casting molds for lightweight engine components, transmission cases, and structural parts. The electronics industry benefits from high-pressure die casting molds for creating intricate components with excellent thermal and electrical conductivity

Similarly, aerospace, medical, and industrial machinery sectors utilize die-casting molds for high-performance components.

From a variety of industries, our clients, including automotive, commercial vehicles, aerospace, and consumer products, turn to TheDieCasting.com for solutions best suited to their needs. Whether it’s crafting lightweight parts for electric cars or precision components for medical devices, our expertise as a leading die-casting tooling manufacturer ensures that every client receives the right solution. Being in direct contact with them, we provide the best designs that fit their needs, complex manufacturing procedures, and excellent services.